Our product lines vary from annealed to heat-treated glass (tempered/heat-strengthened). We offer double-glazed units for curtain walls, single-drilled glass, back-painted glass, and sand-blasted glass. Special designs are provided under special request as well.

When establishing Tempo Glass, a wide search for the best machine vendors was conducted. We do not tolerate technology ensuring the best productivity is achieved.

1. Cutting Machine

Tempo Glass’s cutting machine is the CNC Genius CT from Intermac. The quality of this machine lies under is automated cutting, fluid ejection, edge deletion and automated breaking table. This assures that the cut dimensions are accurate with and international standard tolerance of 1 mm.

2. Double Belt

When most glass processing factories use manual edging, we at Tempo Glass use the automated double belt machine. The machine is known to provide the best grinding in the market.

3. Edging Machines

Instead of having 1 edging machine, we chose to have 2 Glaston edging machines. This decision was made to expand productivity without tolerating quality.

4. Drilling Machine

We also acquire a 2-way automated Glaston drilling machine. We use diamond drilling material to minimize breakage and defects.

5. Tempering Furnace

Our SouthTech tempering and bending furnace is one of a kind. We can heat treat glass up to 5000 mm in length and 2600 mm in width. Additionally, the bending section is 2500 mm * 2500 mm. Our furnace can process Double & Triple Silver High Performance Glass.

6. Insulating Glass Machine

We operate on a Lisec Tal 60 double and triple glazing Semi-automatic machine with the ability of processing shaped and stepped glass.

7. Heat Soak Test

Applying our future vision, we recently purchased a Heat Soak Testing Machine to ensure no sudden breakage occur to our supplied units. This gives us a competitive advantage and enhances quality objectives.

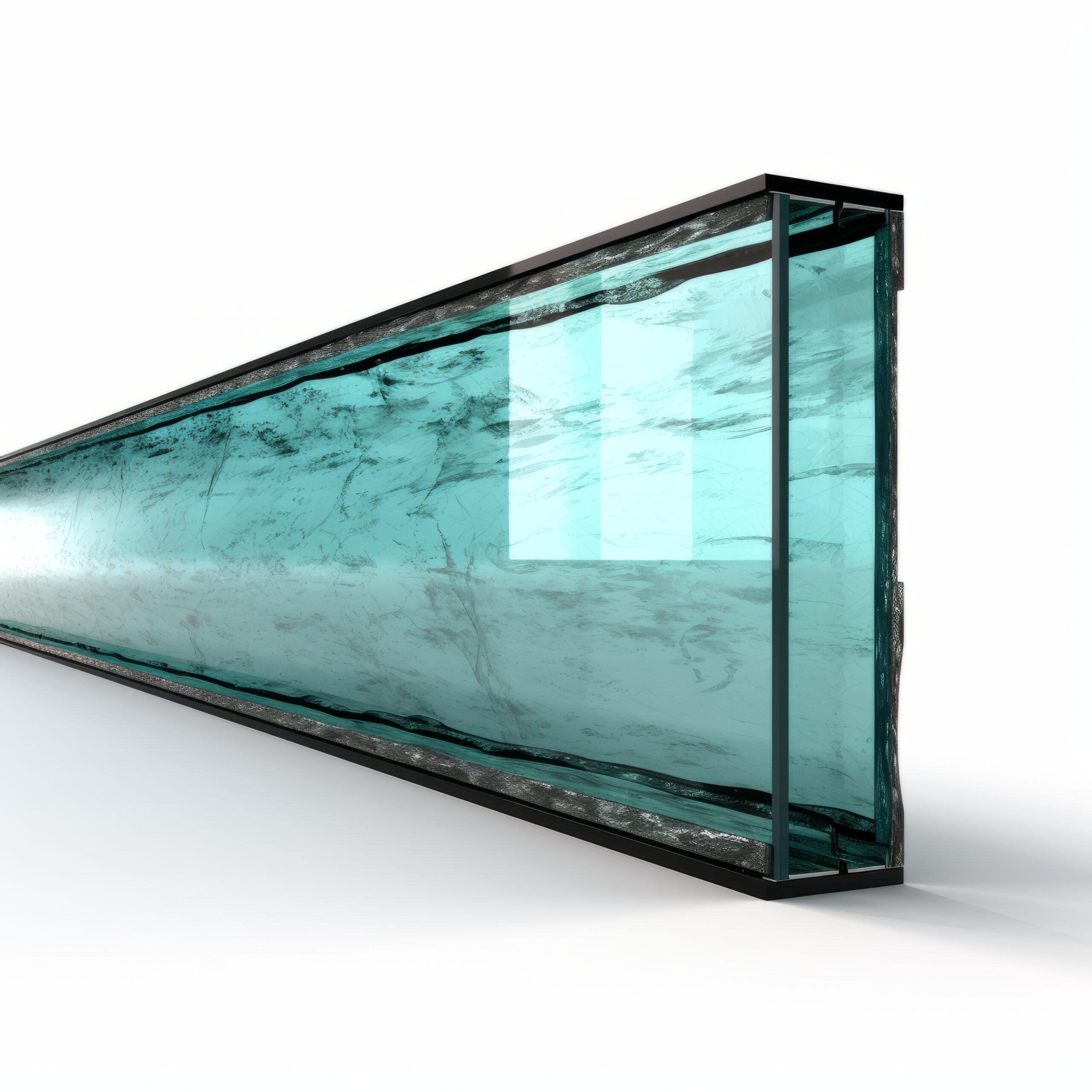

8. Lamination Line

To complete the set of machines we have, an automated lamination line with autoclave was added. Seeking perfection, we chose a 6 m * 3 m line to achieve full productivity. A competitive advantage of using SGP structural PVB is also available.

9. Sand Blasting & Painting Section

A full section is dedicated to decorative sand blasted and painted glass in our factory.

10. Fusing Furnace

Our advanced fusing furnace precisely heats and molds glass into any desired shape, ensuring seamless fusion for custom designs. Perfect for artistic and industrial applications, it accommodates all types of glass with precision and reliability.